Water Hardness for Boilers & Cooling Towers

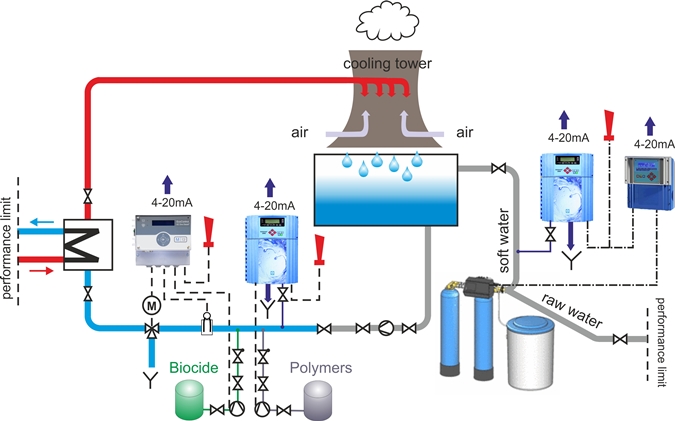

In-Line Process Water Hardness Monitoring:

Monitoring the quality of the water used in Boilers and Cooling towers is a vital step that can help a facility conserve on energy costs. Studies have been performed in Germany that show that a 0.04 inch layer of lime scale build up in a boiler can reduce heat transfer by up to 30%.

So how do down-times associated with boiler maintenance due to lime scaling affect your facility?

Plant operators and facility managers can significantly lower costs associated with lime scaling by continuously monitoring water hardness in their boilers with a Heyl Brothers online water quality analyzer.

Industries include:

Pulp & Paper, Chemical & Pharmaceutical, Mining, Building Materials, Microelectronics/Semiconductor, Food & Beverage, Power Generation, etc..

Applications:

- Industrial Process Water

- Boiler and Cooling Water

- Municipal Drinking Water

- Desalination Plants

- Reverse Osmosis Plants

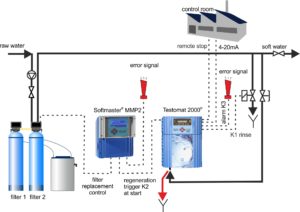

- Water Softening Plants

- Commercial Bakeries

- Breweries

- Meat Processing Facilities

- Dairy Farms

- others

Testomat™ 808

This analyzer is to be used in water treatment (e.g. osmosis plants, electroplating, large boiler plants, laundries, large food service kitchens). The 808 is a limit-value instrument that automatically monitors the residual total hardness (water hardness) in water.

- Self-Cleaning measuring chamber

- Low water consumption

- Cutting edge electronics

- State of the art indicator pump system

- Error display

- Indicator quality display

- External flush valve control

- Limit value evaluation / external control

- Alarm processing

- Internal and external flushing via manual control

- 72 Hours of unsupervised operation possible

- Two Selector switches for interval measurement and limit evaluation

Testomat™ ECO –

This analyzer determines water hardness fully automatically via titration. The instrument is ideal for monitoring and controlling water quality. Applications include water treatment plants, water softening plants – RO and drinking water plants, as well as for monitoring industrial sized boilers or product and feed water (pharmaceutical industry, hospitals and hotels)

- Selectable hardness unit in “dH. °f, ppm CaCO₃ or mmol/l

- High Measurement accuracy ensured by a precise piston-dosing pump

- Analysis frequency: Automatic interval operation (1-99 minutes), external control or quantity dependent via impulsive water meter

- Two independent limit values with hysteresis (1, 2 or 3 analyses with negative results) and settable switch functions

- Reliable and low maintenance operation

- Simple, menu driven operating and programming via a plain text display

- Extended operating periods due to 500 ml indicator storage bottle

- (Two neutral change-over contacts)

- Fault message output (Neutral change-over contact)

Testomat™ EVO TH –

This analyzer is designed for use in the field of water treatment (e.g. osmosis plants, electroplating, large boiler plants, laundries large food service kitchens) the feed water must be clear, colorless and free of un-dissolved particles.

Advantages:

- In-line process water monitoring

- Automated data storage & data transfer via WLAN Access / 4-20 mA / RS-232 interface

- Saving Operational costs due to time scale prevention & lower maintenance

Features:

- Selectable hardness unit in “dH. °f, ppm CaCO₃ or mmol/l

- High Measurement accuracy ensured by a precise piston-dosing pump

- Analysis frequency: Automatic interval operation (1-99 minutes), external control or quantity dependent via impulsive water meter

- Two independent limit values with hysteresis (1, 2 or 3 analyses with negative results) and settable switch functions

- Reliable and low maintenance operation

- Simple, menu driven operating and programming via a plain text display

- Extended operating periods due to 500 ml indicator storage bottle

- (Two neutral change-over contacts)

- Fault message output (Neutral change-over contact)

- Integrated SD card for logging of data, alarm, error messages; Firmware update

- Transfer of Measuring date and status via RS232 interface

- Optional WLAN Access for wireless write access on SD card or connection to fieldbus converter

Testomat™ 2000 – One device, many parameters.

Automatically determines water hardness, the carbonate hardness, the p-value or the minus m-value via titration.

- Selectable hardness unit in “dH. °f, ppm CaCO₃ or mmol/l

- High Measurement accuracy ensured by a precise piston-dosing pump

- Analysis frequency: Automatic interval operation (1-99 minutes), external control or quantity dependent via impulsive water meter

- Two independent limit values with hysteresis (1, 2 or 3 analyses with negative results) and settable switch functions

- Reliable and low maintenance operation

- Simple, menu driven operating and programming via a plain text display

- Extended operating periods due to 500 ml indicator storage bottle

- (Two neutral change-over contacts)

- Fault message output (Neutral change-over contact)

There are a number of models and options available depending upon you application. For best results contact us at Memeco today and let us help you select the best model and accessories for your application. 1-847-329-9393 or info@memecosales.com

Leave a comment