Multi-Metals Continuous Water Analyzer

Th e Xact® 920 system uses reel-to-reel filter tape sampling and nondestructive X-ray fluorescence (XRF) analysis to monitor aqueous samples for user-selected metals. A measured amount of unknown sample is blended with a known amount of internal standard which is then aerosolized and dried facilitating the removal of water and allowed metal salts to be concentrated on the filter tape. This method of pre-concentration allows

e Xact® 920 system uses reel-to-reel filter tape sampling and nondestructive X-ray fluorescence (XRF) analysis to monitor aqueous samples for user-selected metals. A measured amount of unknown sample is blended with a known amount of internal standard which is then aerosolized and dried facilitating the removal of water and allowed metal salts to be concentrated on the filter tape. This method of pre-concentration allows

detection limits in the low parts per billion (ppb) ranges for elements ranging from potassium to uranium.

The concentrated deposit is automatically advanced and analyzed by XRF for selected metals as the subsequent sample is collected. Sampling and analysis are performed continuously and simultaneously, except during advancement of the tape (~20 sec) and during daily-automated qualityassurance checks.

Features

- Sampling, analysis, and near-real time reporting (every 15, 30, 60, and

120 minutes in ppb) - Automatic quality assurance, alarms, and control features

- Proven XRF and RTR technology

- Identification and measurement of 23 elements simultaneously

- Incorporates an XRF stability check with every sample analyzed

- Provides an automatic daily upscale and QA check

Benefits:

- Highly sensitive and reliable (low ppb to ppm range)

- Nondestructive analysis allows for sample archiving

- Low maintenance cost

- Extremely stable, requiring only automated calibration checks

- Analytical recalibration frequency generally less than once per year

APPLICATIONS:

The Xact® 920 monitoring system can simultaneously identify and measure multiple metals in liquid samples to provide data for use in the following applications:

- Waste water and water treatment plants

- Industrial and mining influent and effluent

- Drinking water

- Food and beverage industry

- Surface water

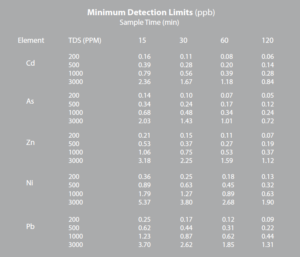

Detection Limits

Elements Supported:

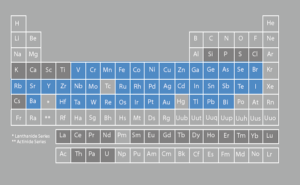

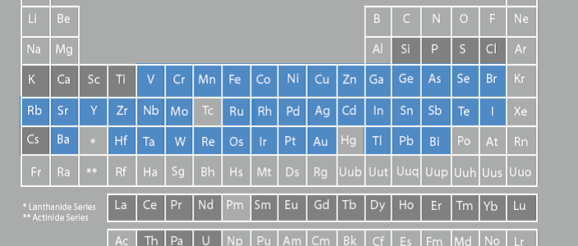

Xact® 920water monitoring systems are capable of the 65 Elements highlighted in the Table Below. The Xact® 920 can measure measure the elements highlighted in grey, but quantification depends significantly on solutions matrix. Please contact us for more information on your specific metals monitoring requirements.

Specifications:

| Measurement method | Based on EPA Method IO 3.3: Determination of Metals in Ambient PM Using XRF |

| Key applicable elements. | Sb, As, Ba, Cd, Ca Cr, Co, Cu,

Fe, Pb, Mn, Ni, Se, Ag, Sn, Ti, Tl, V, Zn, and more available |

| Measurement Range | 1,000ppm of any analyte |

| Detection Limits | Depends on specific metal, sampling times, interfering metals, and level of dissolved solids. See performance section. |

| Sampling and analysis times. | Every 15, 30, 60, or 120 minutes, depending on the per sample dissolved solids |

| Calibration stability check frequency. | Automatically with each sample analyzed |

| Estimated recalibration frequency | Annually, when manufacturer’s operating recommendations are followed |

| Sample flow rate. | Application specific |

| Linearity | Correlation coefficient >0.98 |

|

Size and weight (2 cabinets). |

19”(W) x 24” (D) x 60” (H)

120 lbs 19 inch (483 mm) rack-mountable components |

|

Required operating environment |

Office environment with temperature controlled to 20±3°C (68°F) |

|

Power requirements. |

120 VAC/60 Hz @ 20 amp circuits

220 VAC/60 Hz 10 amp with an optional power converter |

| Outputs | RS232 Modbus signal

Selected analytes plus quality control parameters are reported |

| Options | Change or add elements

Enclosures (NEMA 4, 4x, 12 or 12x) Remote control Remote polling |