CEMGAS Laser 5000 Analyzer

Real Time Gas Measurement with improved Laser Spectrometer Performance

- Process Gas Applications – Coal Fired Utilities

- Incineration – Pulp and Paper – Refineries

- Steel & Metals – Landfills – Biomass Boilers

The CEMGAS 5000

Analyzers by AP2E

“Patented low pressure sampling technology”

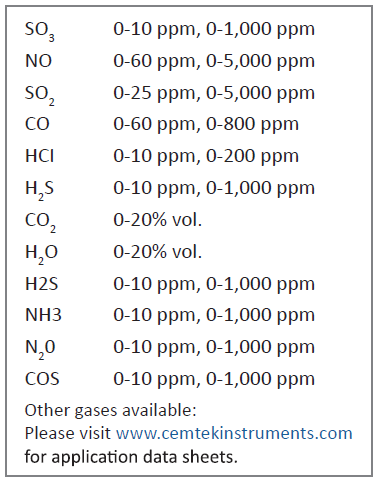

Gases Measurement

(other gases available)

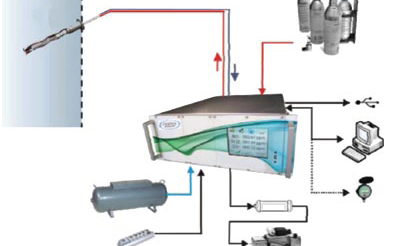

System configuration options include:

- HVAC Cabinet/Shelter

- Data logging

- Calibration Gas Station

- Air Clean Up Panel

CEMGAS 5000 technology spotlight:

Low Fouling / Low Maintenance – Reducing pressure proportionally reduces the amount of sample that may absorb to – desorb from the walls of the sample lines. Operating at a low pressure reduces the risks of false response caused by sample line memory effect

Improved Accuracy :

Reducing pressure (which automatically reduces sample temperature as well) proportionally reduces chemical reaction rates in the sample transfer line. This improves the measurement accuracy by improving representatively of the sample gas

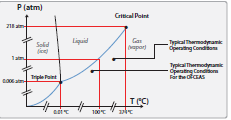

No Moisture Removal Required:

Operating at Low Pressure in the entire sampling system considerably lowers the dew point of the condensable present in the stream.in most cases the sample can be analyzed without sample conditioning.

No Spectral Overlapping / Cross Response:

When lowering the pressure of the gas sample, the spectral absorption bands narrow to the point where there is no spacial overlap.

Sampling Process: – The Sonic Probe allows for extremely low intake flow rate, which enables extremely low fouling of the sampling Probe filterand reduces maintenance requirements. No Moisture or Particulate clean up required.

Operating at a reduced pressure in the entire sampling system (from the sonic nozzle through the measurement cell to the sample pump) allows the unit to work at a much lower dew point. This low dew point allows the system to operate without any traditional sample conditioning. If the sample line temperature dropps below the dew point temperature or if the water vapor concentrates increases, the sample line only needs to be treaced at a temperature above the dew point.