Biological Removal of Phosphorous with Large Bubble Mixing

Biological Phosphorous Removal using Large Bubble Mixing

- At the City of Richmond, IN, Larry Bell, of Bell Mixing Systems designed a system which removed all the diffusers in the first pass of an aeration basin

- The anoxic phase results in producing bacteria which convert the Phosphate as follows: PO4 + PAO’s -àElemental Phosphorous + O2 (A Saleable Product) The bacteria are commonly referred to PAO’s OR Phosphorous Accumulating Organisms

- The customer after our installation provided us this graph: Incoming Phosphate & Outgoing Phosphate, and you can see the Phosphate dropping from 10 mg/l to 0.8 mg/l, for over a 100% reduction.

VERTIMIX is an ideal solution for any mixing application found in a municipal or industrial plant.

Anoxic zones & micro-Organisms

- Large Bubble mixing keeps the bottom of the tanks clean so you will have improved BOD removal of pollutants and everything else down stream With out mixing the Sludge becomes septic and it adds oxygen demand to the whole system. This is why most plants have larger blowers and to many diffusers

- Competitive advantage over other micro-organisms so you are assisting the anoxic micro-organisms to out compete the aerobic bacteria

- The bacteria in the anoxic zones will consume the Phosphate PAO’s which will assimilate the Phosphorus into their cells. Basically, they get fat and settle out in clarifiers.

- This will help save you on Alum (the problem is with out proper mixing you get more sludge if you try to do it with just chemicals)

- Keep Oxygen below 0.2 mg/l for optimum conditions for the right PAO’s to assimilate the Phosphorus into their BIOMASS.

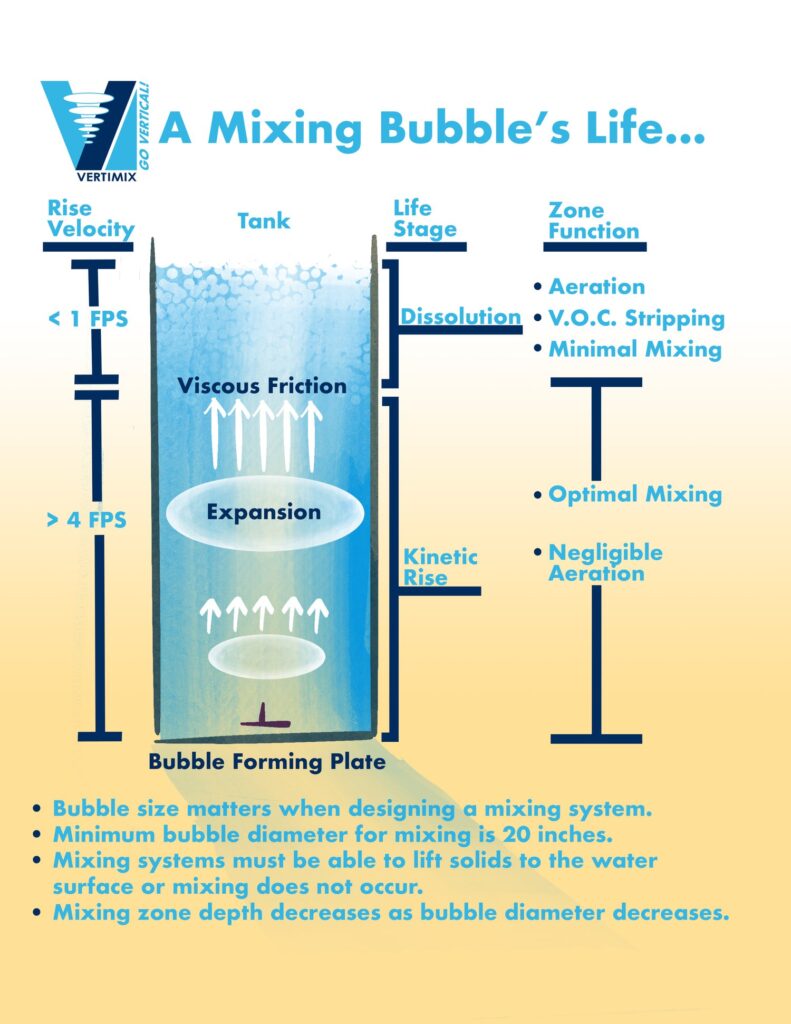

The key to effective mixing is achieved by proper sequencing of very large air bubbles. each bubble contains 2-4 cubic feet of air and requires approximately ½ to 1 hp of energy to create. Depending upon the application, the system will require 2-6 bubbles per minute per valve to mix the material in the tank.

Simplicity in design, effective mixing, and the low power requirement makes anything considered a liquid a candidate for large bubble, vertical mixing.

Think about this: Gravity is FREE!

When you release a LARGE bubble, the upwards force is so great, it moves more water than a propeller blade because it has more surface area than a propeller blade. The force created by a large bubble is so great, it does not matter if the liquid is 2 feet deep or 20 feet deep, it gets the work done.

Vertimix has no parts in the water, doesn’t require large amounts of electrical power, doesn’t have moving parts, doesn’t wear out with time, The only part of the system in the water are the hose and the bubble forming plates, which have no moving parts. So maintenance on that is almost ZERO (the bubble forming plate can be made of CPVC plastic, or Stainless Steel.

Large bubble mixing has been proven NOT to impart oxygen to the water therefore it can be used in Anoxic Zones!

Case Study

A plant in Richmond, Indiana went from requiring $100,000 per year of electrical power to now using only $ 45,000 per year of power. The electrical savings more than paid for the entire system. They also changed out the blowers to smaller blowers, and got better performance. See recent article in TPO Magazine.